The latest generation of near-infrared (NIR) spectroscopy systems designed for on-line measurement of grain, flour, and semolina properties opens up new possibilities for measuring gluten, water absorption, and starch damage. These additional measurements allow millers to optimize flour production directly and individually.

The latest generation of near-infrared (NIR) spectroscopy systems designed for on-line measurement of grain, flour, and semolina properties opens up new possibilities for measuring gluten, water absorption, and starch damage. These additional measurements allow millers to optimize flour production directly and individually.

The grain processing industry has been using NIR systems to continuously monitor the contents of raw, intermediate, and end products for years. More and more companies are now taking advantage of this technology to optimize processes in real time. Using NIR analysis, it is possible to assure consistent product quality, which makes a substantial contribution to the profitability of a mill.

New Generation of NIR

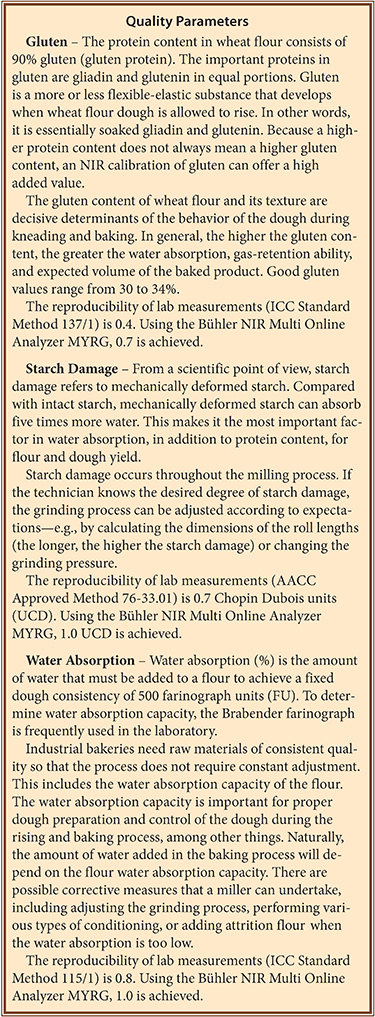

The focus for the first generation of NIR equipment was analysis of protein, moisture, and ash contents. These parameters were, and still are, the “classics” of most on-line systems. There are, however, additional quality specifications with which mills must comply. For example, in wheat flour the amount of gluten, the ability of the flour to absorb water, and the extent to which the starch has been damaged are also important factors. Older generations of on-line NIR systems were not able to determine these parameters with sufficient accuracy and reproducibility. By employing photodiode (PD) arrays, the latest generation of NIR systems (e.g., Bühler NIR Multi Online Analyzer MYRG) offers new possibilities for accurate measurement of additional parameters and, thus, new potential applications for millers (Fig. 1). These additional calibrations eliminate long periods spent waiting for laboratory results and allow corrective measures to be performed without delay

Possible Applications for NIR

NIR spectroscopy is very well suited for determining the most important contents in organic materials such as grain food and feed products. To provide accurate analyses, however, an NIR system not only needs high-quality hardware to function reliably, but a good mathematical model (calibration) to determine the properties of an unknown product.

The most important and NIR-active biochemical components, such as water, starch, protein, and fat, can be modeled (or calibrated) without difficulty. However, other physical or biochemical product properties can also be correlated with NIR spectra, as long as they are dependent on the combination of the dominant contents and other properties, such as particle size distribution. An example of this is the ability of flour to absorb and retain water during the making of dough. The ability of flour to absorb water depends on the volume and quality of the protein, condition of the starch, and particle size distribution, among other things.

Limitations of NIR

Only those characteristics that actually leave information in the NIR spectra and correlate with them can be calibrated. An example of this is the “sample” that is used to evaluate the activity of certain enzymes in flour. NIR technology is only conditionally suitable for lower concentration ranges. It is technically impossible to calibrate enzymes for NIR because it takes only a few parts per million of enzymes in flour to become active.

To generate NIR calibrations, the breadth of data is key for the accuracy and sturdiness of the model. Models can only predict products if their characteristics have already been included in the model itself. On the one hand, it is essential to cover the entire range of features that are to be measured, because the models are not allowed to extrapolate. On the other hand, any factors that cause a disturbance, such as specific product characteristics (e.g., particle size, temperature, source, chemical composition), the instrumentation used, and the surroundings, must also be taken into consideration, along with the characteristics that are supposed to be measured. For the best calibration, several hundred samples can easily be necessary under these conditions.

To generate NIR calibrations, the breadth of data is key for the accuracy and sturdiness of the model. Models can only predict products if their characteristics have already been included in the model itself. On the one hand, it is essential to cover the entire range of features that are to be measured, because the models are not allowed to extrapolate. On the other hand, any factors that cause a disturbance, such as specific product characteristics (e.g., particle size, temperature, source, chemical composition), the instrumentation used, and the surroundings, must also be taken into consideration, along with the characteristics that are supposed to be measured. For the best calibration, several hundred samples can easily be necessary under these conditions.

NIR Process

To compare spectra and samples, data must be prepared and calculated using certain algorithms (chemometry). The preparation of the spectra data using various mathematical functions depends on the product itself, as well as the hardware used, and is necessary for better separation of information of interest (such as protein content) from information that is not of interest (such as particle size distribution). Various possibilities exist that fall under the skill set of chemometricians. Quantitative calibration models are usually calculated using the PLS (partial least squares) algorithm, which searches for the largest differences in spectra and links these with the characteristics to be calibrated.

Working with NIR Systems

The accuracy of an on-line NIR measurement system is usually indicated by the SEP (standard error of prediction). SEP is a random standard error that is found between the reference laboratory and the on-line measurement during at least 20 validation measurements. The random error in the NIR (SEP) system cannot be smaller than the random error of the lab (SEL), because the calibration is based on the data from the reference laboratory. For samples lacking homogeneity, from which taking a representative sample is already challenging, an on-line NIR measurement can be significantly more accurate simply because of the size of the sample volume and the frequency of the information being read out.

NIR devices require constant adjustments. The hardware (i.e., light source, measuring window) must be checked frequently, and the NIR calibrations themselves also need to be monitored regularly and fine-tuned, because the product can undergo natural changes in unknown directions over time.

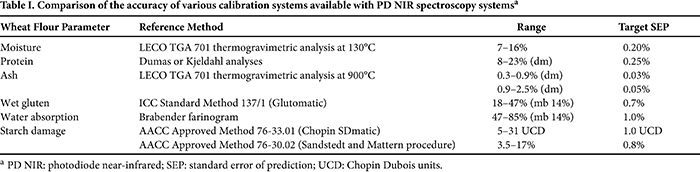

Accuracy of NIR

The accuracy of the various calibration systems available with PD NIR systems is summarized in Table I. A comparison of the SEP values with the accuracy of the standard lab methods shows that the newest generation of NIR spectrometers can determine additional parameters in continuous production with amazing accuracy.