|

|

02 Features

Cereal Foods World, Vol. 63, No. 2

DOI: https://doi.org/10.1094/CFW-63-2-0056

Print To PDF

DisplayTitle Flour Quality and Artisan Bread

Abstract

CFWAbstract A technical definition of artisan breads is proposed based on the concepts of lean formulations, long fermentations, and the use of process as the primary way to adapt to changing flour qualities. The current status of what constitutes refined flour that is suitable for artisan bread production is discussed. A conclusion is drawn that very high protein flours that create very strong doughs are likely not to be optimum for artisan breads. Because the long fermentations used in artisan production create acidified doughs, even when only baker’s yeast is used, the effect of long fermentations on acidification and its impact on dough strength are also covered. In addition, the article discusses the state of the art in the rapidly changing world of whole wheat baking at the artisan level, where the use of ancient and heritage wheats with weaker dough properties is growing, along with the use of modern hexaploid wheats with more conventional, “normal” dough performance. Preliminary data suggesting that whole wheat sourdough breads respond to different aspects of flour quality compared with refined flour straight-dough breads are also presented.

Trying to reach content?

View Full Article

if you don't have access, become a member

Page Content Because hearth breads have so few ingredients (basically flour, water, leavening, and salt), and because they have been made for centuries, one is tempted to oversimplify the process. –James MacGuire (6)

Flour quality for artisan bread—where do we even start? Are we in danger of oversimplifying the process, in part because there are so many kinds of bread that can be considered “artisan”? The philosophy of what constitutes artisan with respect to breadmaking is covered elsewhere in this special issue of Cereal Foods World (47), but clearly there is a need to define a target from a technical perspective. To manage the scope of this article, it is focused on lean-formulation, risen breads and not on enriched-dough products, such as panettone or brioche, that are legitimately “artisan” when made using traditional processes. This article does not aim to be the definitive tract on the topic but, rather, to be a conversation starter. The article also has an unavoidable North American bias as a result of the author’s domicile there.

To get a better idea of the technical framework surrounding artisan breads a series of interviews was conducted within the artisan baking community, both in the United States and Denmark. All of the interviewed bakers and millers espoused a common theme: for artisan breads and processes, within certain constraints, the process can be adapted to the flour. This conclusion is supported by Leonard (28), who wrote that an artisan baker “adapts each formula and the timing of mixing, rest, scaling, molding and proofing, to variances in [among other factors] the quality of flour.” In contrast, the interviewees suggested that in modern high-speed, continuous, industrial processes, because of their comparative inflexibility, in a sense, the flour needs to be adapted to (i.e., chosen specifically for) the process. The interviewees suggested that the adaptability of artisan processes results from the employment of well-trained bakers, use of modular or batch processes, judicious use of retarding, and use of hand-shaping, the latter even in facilities processing upwards of 5,000 kg of dough per day. Because of their relatively lower capacity for adapting to variability, industrial processes require greater levels of consistency in flour and dough performance. They also arguably require stronger dough characteristics than might be considered optimum for most artisan-style breads. Obviously, there is considerable overlap somewhere between the two extremes: no artisan process is infinitely flexible, and no industrial process is infinitely inflexible.

From a technical viewpoint, artisan breads and processes could be defined by the following factors:

- The use of lean formulations generally consisting only of flour, water, salt, and microbial leavening. Additional ingredients aimed specifically at improving flour functionality are restricted to diastatic malt flour and occasionally ascorbic acid. The use of fats, oils, and sweeteners is restricted to specific bread types.

- Despite the simple formulation template, there is a large variety of breads, and many types are baked directly on the hearth, unsupported by a pan.

- The frequent use of high hydrations, creating soft doughs that are not easily machined.

- A strong focus on long preferments using either commercial yeast or Lactobacillus species-based mixed cultures (also known as levains or sourdoughs) perpetuated by traditional type 1 back-slopping procedures (12,19).

- The use of gentle mixing and dough development techniques. These are used, in part, to maintain the color of the endosperm carotenoid pigments by limiting their oxidation (5,6,33,40).

- An emphasis on flavor development, both through long fermentations and the use of higher ash flours that have been shown to have a positive influence on fermentation vigor (40) and bread flavor (24), arguably through increased metabolite production (39).

- Hand-shaping or minimal and gentle machine-shaping.

- The use of process changes as the primary strategy to address changes in flour characteristics and dough properties and maintain finished-product quality, rather than the use of processing aids such as dough conditioners. For example, in yeasted breads, increasing dough strength or adapting to flours with poor fermentation tolerance by adding greater levels of preferments (40,47).

- A broader view of the traits that constitute the totality of processing quality and finished-product excellence (26,36): for example, flavor, aroma, open crumb textures with a creamy appearance, crust crispiness, quality and appearance of cuts on the bread, and adherence to type when traditional breads are produced, among others.

In addition to technical considerations, in my experience, artisan bakers are trend leaders, guiding the way to a more thorough appreciation of the array of traits that create exceptional bread quality. Artisan bakers are more frequently using older wheat types with weak dough properties (6,26) and, as noted above, refined or semirefined flours with high ash contents. Artisan bakers are also exploring hulled wheats (einkorn, emmer, and spelt) for use as raw materials in regions where their use has diminished, such as North America (15,34). A newer factor is a growing focus on the flavor, aroma, and health potentials of whole grain flours, which are increasingly milled either in-house, primarily using stone mills, or sourced from small- to medium-scale and specialty milling companies. Locally or regionally grown grains are often used and fermented using sourdough for both its ability to enhance flavor and its potential nutritional benefits (11,12,23,37).

Refined Flours

There are few concrete frames of reference for assessing refined flour qualities for artisan breads given the wide variety of bread types produced, each of which has quite different optimum flour characteristics. The one seemingly invariable factor in the craft-baking community, at least in the United States, is the use of unbleached refined flour. This is connected to the desire to retain the endosperm carotenoid pigments for color and flavor (6), although Myhrvold and Migoya (33) have disputed the flavor factor and suggested that retaining pigmentation only impacts the aesthetics of breads. When breeding common wheats specifically for artisan breads, however, selecting genotypes with a high lutein content (endosperm yellowness) that persists into the finished product may also provide, beyond the aesthetic and flavor dimensions, health benefits for consumers, as has been suggested for durum wheats (5).

An online survey of refined flours sold specifically as professional “artisan bread flours” in the United States revealed a divergent set of specifications. Refined flour protein contents ranged from 11.5 to 14.0%, and ash levels ranged from 0.48 to 0.80% (all ash and protein contents were reported on a 14% moisture basis unless otherwise noted). There were very few easily available examples of certificates of analysis or more detailed specifications related to dough mixing or strength properties. Where specifications were available, they indicated the flours created doughs of intermediate mixing time and intermediate tolerance to overmixing. Breadlines, the Bread Bakers Guild of America trade magazine, published a desired specification for U.S. flours used for artisan breads of 11 to 12% protein, 0.48 to 0.54% ash, a flour falling number of 250 to 290 sec, farinograph absorption of 60 ± 2%, and stability time of 10.0 ± 2 min (18). These specifications correspond closely to the published specifications of a number of commercial refined flours targeted at artisan bakeries. They also conform somewhat to the protein ranges and strength characteristics suggested for risen breads recommended by Wrigley et al. (46): >11% with medium dough strength to >12% with medium to strong dough. However, for panned sandwich breads Békés et al. (3) suggested strong doughs made from flour with >13% protein. The wheat varieties for these stronger doughs are designed, through selection of desired glutenin compositions, to minimize bubble coalescence in dough foams through high levels of strain-hardening in extension (8). These flours, therefore, are also associated with fine, even crumb structures and are not necessarily compatible with the more rustic, open crumb structures associated with artisan breads—the archetype being the baguette (Fig. 1). An online survey of refined flours sold specifically as professional “artisan bread flours” in the United States revealed a divergent set of specifications. Refined flour protein contents ranged from 11.5 to 14.0%, and ash levels ranged from 0.48 to 0.80% (all ash and protein contents were reported on a 14% moisture basis unless otherwise noted). There were very few easily available examples of certificates of analysis or more detailed specifications related to dough mixing or strength properties. Where specifications were available, they indicated the flours created doughs of intermediate mixing time and intermediate tolerance to overmixing. Breadlines, the Bread Bakers Guild of America trade magazine, published a desired specification for U.S. flours used for artisan breads of 11 to 12% protein, 0.48 to 0.54% ash, a flour falling number of 250 to 290 sec, farinograph absorption of 60 ± 2%, and stability time of 10.0 ± 2 min (18). These specifications correspond closely to the published specifications of a number of commercial refined flours targeted at artisan bakeries. They also conform somewhat to the protein ranges and strength characteristics suggested for risen breads recommended by Wrigley et al. (46): >11% with medium dough strength to >12% with medium to strong dough. However, for panned sandwich breads Békés et al. (3) suggested strong doughs made from flour with >13% protein. The wheat varieties for these stronger doughs are designed, through selection of desired glutenin compositions, to minimize bubble coalescence in dough foams through high levels of strain-hardening in extension (8). These flours, therefore, are also associated with fine, even crumb structures and are not necessarily compatible with the more rustic, open crumb structures associated with artisan breads—the archetype being the baguette (Fig. 1).

Despite the fact that many of the commercial resources reviewed insisted that flour for hearth breads should have a high gluten content and strong dough characteristics, the popularity of lower protein flours with less absolute strength for use in artisan breads has evidence to support it. For example, Paulley et al. (35) showed that a lower protein (12.0%) Canadian Western Red Spring (CWRS) wheat flour had better overall performance in a Uruguayan French bread process, with fermentation times of up to 75 min, than did a 13.8% protein CWRS wheat flour. Færgestad et al. (10) found that form ratio (height/width) was positively related to dough resistance and the presence of high molecular weight glutenin subunits 5+10 when using a low-speed mixing process relevant to artisan processes. Loaf volume was positively correlated with dough extensibility and protein content. Loaf volume and form ratio at a fixed mix time using low-speed mixing were negatively correlated. This suggests that for flours with strong dough characteristics full volume potential was not realized with gentle mixing, which may have insufficiently developed their glutens, and may suggest these flours are not suitable for use in artisan processes that employ minimal mixing. Tronsmo et al. (43) showed that although higher flour protein contents were associated with increased pan loaf volumes, a higher flour protein content and increased monomeric to polymeric protein ratio were associated with lower form ratios in hearth loaves. They concluded that “higher flour protein content [was] not necessarily advantageous for the properties of hearth loaves.” This conclusion fits with the practice by many artisan bakers of using bread flours with 11–12% protein.

The concept that lower protein bread flours with intermediate dough strength may be optimal for use in artisan breads is also supported by observational evidence in the craft-baking community. Forestier (9) wrote that use of flours with protein contents of 14% or higher is often advocated for artisan breads. However, she suggested that despite their ability to be “stretched without tearing,” a tendency to buckiness makes them unsuitable for the long fermentations that are necessary for flavor development. She also observed that high-protein flours were associated with tough crust and crumb textures. Huff (18) indicated an optimum flour protein content between 11 and 12%. Suas (40) wrote that flour milled from U.S. hard red winter (HRW) wheat (by inference not as strong or as high in protein as U.S. hard red spring [HRS] wheat flour) is preferred for long fermentations because its fermentation tolerance (defined in that reference as “the ability of the gluten structure to maintain its shape in a dough system during long fermentation times” [40]) is better. There is no consensus definition for “fermentation tolerance,” and most of the commercial milling company websites and product brochures indicate that their high-gluten flours have excellent fermentation tolerance, which contradicts the experience and observations of Suas (40); there is no clear answer to this conundrum. Suas (40) also indicated that very strong doughs produced finished-product defects, including shorter loaves with round cross-sections with cuts that did not open correctly.

To look more closely at the differences between winter and spring wheats in the United States, the 2017 U.S. Wheat Associates crop report (44) was consulted. This report showed that U.S. HRW wheat had 5 year average values of 12.6% for grain protein (corresponding to around 11–11.5% flour protein), 0.56% for flour ash, farinograph absorption of 59.5%, and farinograph development and stability times of 5.2 and 9.2 min, respectively. These values correspond remarkably well with the desired specifications for U.S. artisan flours noted earlier (18). For the HRS crop the 5 year average values were 14.0% for grain protein (corresponding to around 12.5–13.0% flour protein), 0.50% for flour ash, farinograph absorption of 63.0%, and farinograph development and stability times of 7.1 and 11.3 min, respectively. The HRS values were generally higher for protein, a little higher for absorption, and stronger for mixing properties than the desired specifications and the HRW values, but not tremendously so. Perhaps more telling regarding the differences between HRW and HRS wheat flours were the extensograph and alveograph data. Extensograph maximum resistance at 135 min (Rmax135: arguably the appropriate metric for long-fermentation doughs) was 476 BU for HRW and 768 BU for HRS. Extensibility at 135 min for HRW flour was slightly better than for the HRS flour (142 versus 137 mm). Calculated Rmax135 to extensibility ratios of 3.4 for HRW flour and 5.6 for HRS flour showed that the HRS-derived doughs had much greater tenacity (approaching double) per unit extension compared with the HRW-derived doughs. These observations lend credence to the remarks of Forestier (9) regarding the apparent buckiness of high-protein flours, which in the United States are commonly milled from HRS wheats. Five year average alveograph work values (W [10–4 J]) were 239 for HRW and 362 for HRS. Calvel et al. (6) provided alveograph W specifications for U.S. wheats “appropriate for the production of French breads” of between 250 and 290, assuming a balanced dough tenacity/extensibility (P/L) ratio. To put this into context, the W values reported by Calvel et al. (6) for French breadmaking flours ranged from 150 to 200, suggesting that even though the 5 year average HRW W value was lower than that specified for HRW wheat flours by Calvel et al. (6) it was still arguably more suitable for French breads than the 5 year average W value of 362 for HRS.

Two other factors may play a role in the desirability of flours with 11–12% protein that create doughs of intermediate strength in artisan baking. The first is the fact that flours with the specifications outlined by Huff (18) are, in a rather uncharitable sense, so unremarkable and middle-of-the-road that they have great potential to be adapted to changes in formulation and process to produce different outcomes in the finished breads. In the hands of a skilled artisan these flours are capable of creating the most delectable, open-structured baguettes at one end of the spectrum and fine-structured pain de mie sandwich breads at the other end through judicious alterations to the process and, in the case of pain de mie, the addition of at least a small amount of shortening. The second factor is related to one of the technical factors suggested earlier as defining artisan processes and breads: the almost universal use of long fermentations. By long fermentation, I mean very often longer than the yeast-based sponges used in sponge-and-dough, industrial-scale sandwich bread production (Cauvain [7] indicates 4–8 hr); in straight-dough, yeast-risen breads, bulk fermentations of at least 3 hr; in yeast-risen breads with preferments, 12–16 hr or more of fermentation before the preferment is added to the production dough; and in sourdough-risen breads, sourdough starters prefermented for between 4 and 24 hr before addition to the production dough (12). In the case of sourdough breads, preferments are often followed by quite long bulk fermentations and proofing times.

The outcome of long fermentation times, for both sourdoughs and yeast-risen doughs is acidification. This seems obvious for sourdoughs, in which the presence of a diverse range of heterofermentative Lactobacillus spp. (12,19) produces levels of lactic and acetic acids above the sensory thresholds for detection in the finished breads. What may be less obvious is the potential for acid production in yeast (Saccharomyces cerevisiae)-risen doughs. The reported sources of acidification in yeast-risen doughs are, first, the production of lactic acid by lactic microbiota that arrive with the baker’s yeast when fermentations exceed 8–12 hr (12) and, second, the production of succinic acid by S. cerevisiae (20,21,25). An enduring assertion by artisan bakers is that acidity strengthens the dough (4,14,32,36,39). This assertion contradicted the understanding gleaned from the literature concerning the influence of acid on gluten proteins, especially decreased mixing tolerance (17,45) and activation of wheat proteases at low pH, which hydrolyzes the gluten proteins (2,12,13). However, other reported evidence does point to a dough-strengthening effect of low pH. Harinder and Bains (16) showed marked increases in resistance to extension in doughs with 1.5% NaCl at pH 5.0 and 4.2 after both 5 and 45 min of resting, with an attendant decrease in extensibility at pH 4.2. Maher Galal et al. (30) showed increases in farinograph mixing and stability times with the addition of a mix of organic acids at concentrations relevant to sourdough bread production and in the presence of 1.5% NaCl. Although Tanaka et al. (42) showed decreased dough consistency and a shortened mix time with the addition of acetic acid they also showed an increased resistance to extension and decreased extensibility at pH 4.2 compared with pH 5.8 in the presence of 1% NaCl. Jayaram et al. (21) reported similar results for both uniaxial and biaxial extension after addition of succinic acid to doughs at concentrations consistent with what is produced by S. cerevisiae during bread fermentations. They concluded that succinic acid led to swelling and unfolding of the gluten proteins that potentially allowed for greater entanglement within the elastic network. This seems to be the most likely cause of the observed increased strength and decreased extensibility. Similarly, lactic acid solutions are known to swell glutenin proteins more than water alone, and this is the basis of the lactic-acid solvent retention capacity test (27). The strengthening effects in sourdoughs may also then be a result of greater swelling and entanglement of glutenins in lactic acid. Additionally, because acidification is a factor in long fermentations, either with sourdough or baker’s yeast, the preference for a flour that, unacidified, creates a medium strong dough can be conceived of as a way to avoid overstrong doughs if starting with, for example, a very strong spring wheat flour.

Whole Wheat and Sifted Flours

If at the start of this article it seemed to be a daunting task to assess refined flour quality for artisan breads, summarizing the modern iteration of whole wheat artisan baking in the United States is even more daunting. It is in this environment that we can observe substantial experimentation involving raw materials, milling, processing, and finished product quality. Modern artisan bakers are reinvigorating the use of einkorn, emmer, and spelt in the United States, partly from a desire to exploit their unique flavor and aroma characteristics. Artisan bakers are compensating for the generally weak dough properties of flours milled from these hulled wheats (15) through alterations in processes or blending with higher strength hexaploid wheat flours. For example, a demonstration at the San Francisco Baking Institute of a high-hydration, whole grain emmer and spelt bread utilized the simple expedient of proofing and baking in pans to accommodate the more fluid nature of the dough (Fig. 2). There is also a fascination in the craft-baking community with older hexaploid wheats that is propelled by a variety of motivations, including the perception that they provide better flavor. I can attest to the distinct and attractive flavor of breads made with the whole wheat Red Fife flours to which I have had access (Fig. 3). If at the start of this article it seemed to be a daunting task to assess refined flour quality for artisan breads, summarizing the modern iteration of whole wheat artisan baking in the United States is even more daunting. It is in this environment that we can observe substantial experimentation involving raw materials, milling, processing, and finished product quality. Modern artisan bakers are reinvigorating the use of einkorn, emmer, and spelt in the United States, partly from a desire to exploit their unique flavor and aroma characteristics. Artisan bakers are compensating for the generally weak dough properties of flours milled from these hulled wheats (15) through alterations in processes or blending with higher strength hexaploid wheat flours. For example, a demonstration at the San Francisco Baking Institute of a high-hydration, whole grain emmer and spelt bread utilized the simple expedient of proofing and baking in pans to accommodate the more fluid nature of the dough (Fig. 2). There is also a fascination in the craft-baking community with older hexaploid wheats that is propelled by a variety of motivations, including the perception that they provide better flavor. I can attest to the distinct and attractive flavor of breads made with the whole wheat Red Fife flours to which I have had access (Fig. 3).

Sources of these flours vary. Large U.S. milling companies may supply both roller-milled and stone-milled whole spring and winter wheat flours. However, whole wheat flours are increasingly being sourced from small- to medium-scale regional flour mills, many of which have only been established in the last five years or so. Some of these mills supply flours milled from a blend of wheat varieties, and increasingly, some mills supply flours from traceable single varieties. Some of these mills sift out the coarse bran, making high-extraction flours that have some of the dough-handling attributes of refined flours. Unfortunately, a mishmash of terminologies, some European (type based on ash content) and some North American (extraction rate conflated as “type”) in origin, is being used to market these sifted flours. The confusion is palpable. Leonard (29) has made a plea for the system to be standardized based on ash levels: for example, a type 85 flour would have 0.85% ash (on a 14% basis or on a dry basis is another argument) and would not be, as some millers are marketing it, an 85% extraction flour. The small mills are most commonly stone mills, but some flour manufacturers use straight-through roller or attrition systems. Sources of these flours vary. Large U.S. milling companies may supply both roller-milled and stone-milled whole spring and winter wheat flours. However, whole wheat flours are increasingly being sourced from small- to medium-scale regional flour mills, many of which have only been established in the last five years or so. Some of these mills supply flours milled from a blend of wheat varieties, and increasingly, some mills supply flours from traceable single varieties. Some of these mills sift out the coarse bran, making high-extraction flours that have some of the dough-handling attributes of refined flours. Unfortunately, a mishmash of terminologies, some European (type based on ash content) and some North American (extraction rate conflated as “type”) in origin, is being used to market these sifted flours. The confusion is palpable. Leonard (29) has made a plea for the system to be standardized based on ash levels: for example, a type 85 flour would have 0.85% ash (on a 14% basis or on a dry basis is another argument) and would not be, as some millers are marketing it, an 85% extraction flour. The small mills are most commonly stone mills, but some flour manufacturers use straight-through roller or attrition systems.

There is also an increasing number of bakeries that are installing their own stone mills onsite. The motivations for this include enabling a closer connection to the farms where the grain is grown, a perception of better flavor derived from very freshly milled grain, and claims of health benefits for very fresh flour, which may not be supported by evidence. However, there is scientific support for the use of fresh-milled whole wheat flours. Mense and Faubion (31) reviewed the effects of aging on both refined and whole wheat flours. Contrary to the improvement in baking quality of refined flours after a period of aging postmilling, they concluded that whole wheat flours provided their best baking performance immediately after milling, observing that whole wheat bread volume slowly decreased over storage time for whole wheat flour, even when the flour was stored at –20°C! The culprit appears to be oxidation of unsaturated lipids (41). Arguably, there are also nutritional consequences. Lipid hydroperoxides created by auto-oxidation or lipoxygenase action are associated with the oxidative degradation of carotenoid pigments (5). Increased levels of lipid hydroperoxides after extended storage of whole wheat flour, which has not been stabilized by heat-deactivated lipases and lipoxygenases, could further degrade lutein in whole wheat doughs during mixing, and loss of this pigment constitutes a small potential decrease in nutritional value.

The flexibility of artisan baking processes plays a key role in this environment. Unless bakers are sourcing their whole wheat flour from large mills they can expect a high degree of variability in the flour they use. This variability can be attributed to several factors. First, when buying grain directly from farmers for in-house milling or when buying flour from small milling operations that are sourcing locally and regionally grown grains, there is no capacity to blend grains or flours to compensate for changes in grain and flour functionality. Bakers need to be aware that even when buying the same variety of wheat grain or flour, baking performance can be altered from one location (farm or field) to another by the growing environment, including soil N status and relative water stress, among other factors. Another variable is the miller and the mill. In stone mills variations in particle size distributions and starch damage may be more difficult to control than in roller mills. Particle size distribution in stone-milled flours does affect baking quality but not as much as the characteristics of the grain being milled (38).

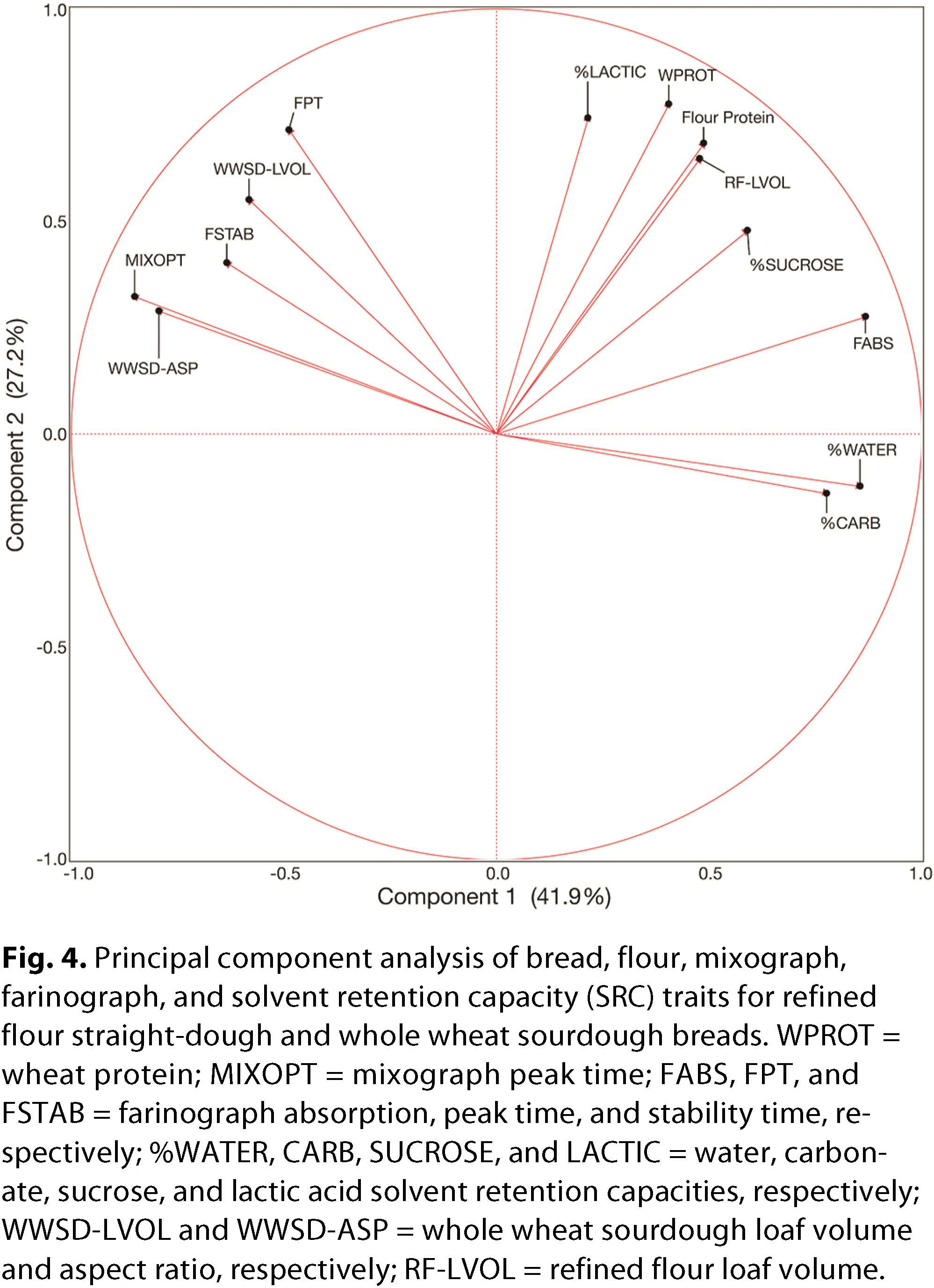

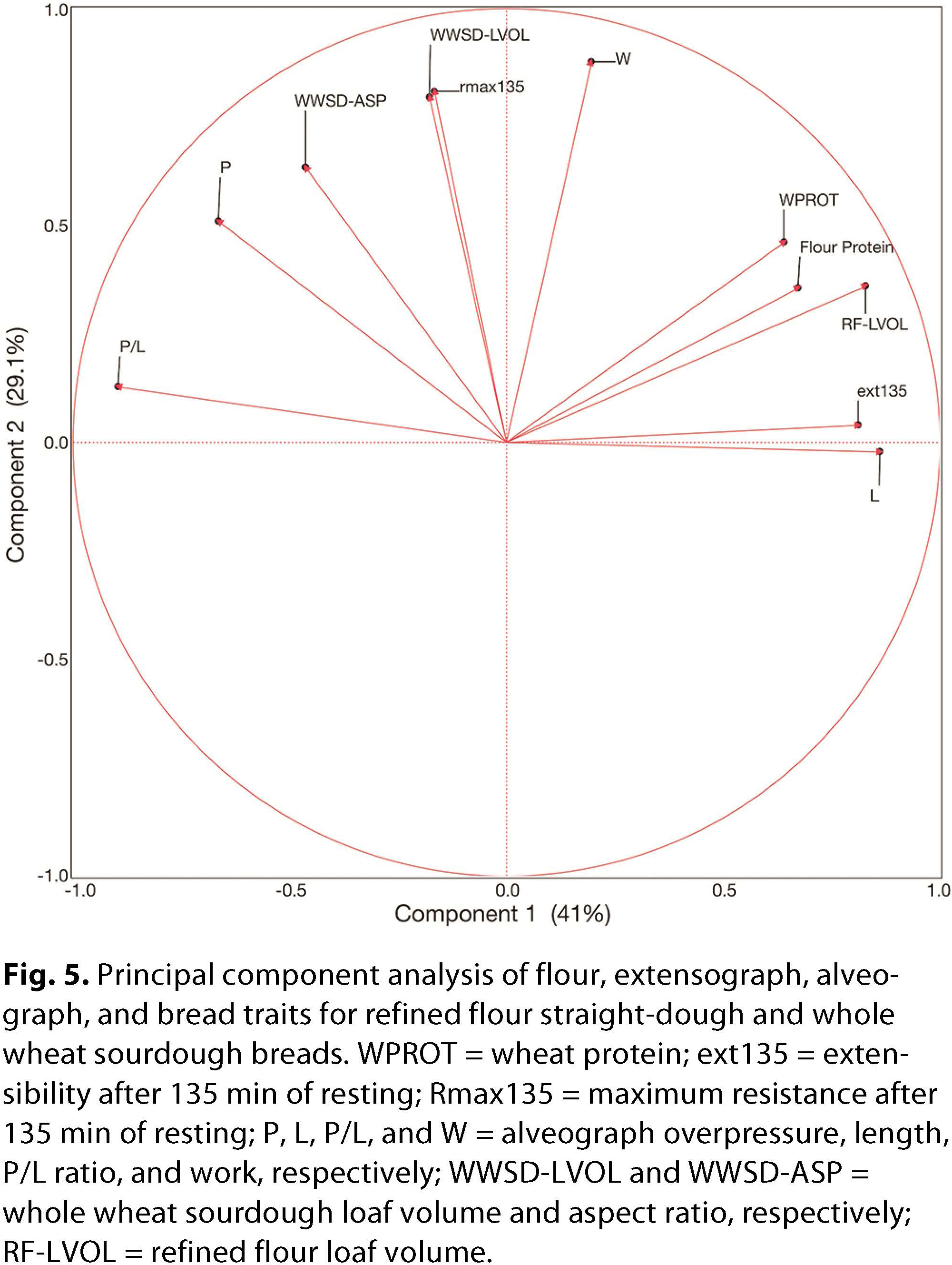

Having the skills and experience to alter fermentation schedules, amounts and types of perferments, and other process steps is key to adapting to this fast-changing aspect of artisan baking. There appears to be no one prescriptive set of flour specifications for whole wheat flours given the enormous range of wheat species and varieties and, as a result, dough characteristics encountered in artisan bakeries around the world. For hard hexaploid wheat varieties, there is preliminary evidence that panned loaf volume in yeast-raised breads made from refined flours responds to different facets of the flour quality profile than does the loaf volume (panned) and free-standing aspect (or form) ratio of whole wheat sourdough breads. The results of principal component analysis (PCA) of refined flour protein, solvent retention capacity, mixograph and farinograph data, and bread data for 25 hard wheat samples, with protein contents ranging from 11.6 to 15.9%, that were submitted to the Pacific Northwest Wheat Quality Council in 2015 are shown in Figure 4. Refined flour straight-dough breads were made using AACC International Approved Method 10-10.03 (1), without optional dough conditioners and oxidizers. Whole wheat sourdough breads were made with 100% whole wheat flour, optimized water addition averaging 85%, and 2% NaCl. Of the total flour, 15% was prefermented at 100% hydration, using a type 1 sourdough starter as inoculum, for 16 hr at 21°C before being added to the production dough. Doughs were mixed to clean up in a 20 qt Hobart mixer, bulk fermented for 3.5 hr at 23°C with three sets of folds at 30 min intervals. Divided doughs were rested (intermediate proof) for 20 min, shaped, and proofed for 1.5 hr before baking. The results illustrated in Figure 4 show that in this analysis refined flour loaf volume (RF-LVOL) was associated most strongly with factors that were correlated with total protein content. This indicates that RF-LVOL in this sample set was responsive to differences in the total protein in the flour. In contrast, whole wheat sourdough loaf volume (WWSD-LVOL) and aspect ratio (WWSD-ASP) were associated most strongly with different aspects of flour quality—farinograph mix time and stability and mixograph peak time—and not responsive to total protein. Flour and wheat protein contents were effectively orthogonal to farinograph peak time and stability and mixograph peak time, suggesting no relationship between the groups of factors. The results of PCA for the same samples versus the extensograph and alveograph data for the refined flour analyses are shown in Figure 5. Once again it is clear the two bread types responded to different aspects of flour quality. RF-LVOL was still associated with total protein, as well as with facets of quality related to increased dough extensibility: that is, positively related to alveograph L value and extensograph extensibility at 135 min and negatively related to alveograph P/L ratio. Again, in contrast, WWSD-LVOL and WWSD-ASP were associated with facets of quality related to dough strength—extensograph Rmax135 and alveograph W and P values—and again, WWSD-LVOL and WWSD-ASP were not systematically affected by total protein. These preliminary data are not definitive but do indicate a fundamental difference between whole wheat sourdough and refined flour straight-dough breads. They also give credence to a comment made by an artisan baker with vast experience, who when switching his entire operation to whole grain flours said that he needed to completely relearn his craft.

Stephen Kaplan (22) had the last word: “The fact remains that [even] with the best raw materials in the world, an ill-trained or insufficiently motivated baker cannot make good bread. This is why…[we] attached so much weight to the competence of the artisan.”

Conclusions

From a technical perspective, artisan breads might best be defined by the use of lean formulations, process changes to adapt to variability in flour and dough performance, and short, gentle mixing and long fermentations. For refined flours there is plenty of precedent established in the scientific and trade literature concerning flour qualities that may best suit artisan bakers—the details of which were laid out in the preceding narrative. However, the emerging focus on whole wheat breads by some bakeries has thrown the door wide open for artisan bakers. We are now seeing the adaptability of artisan processes and thinking applied to an astonishingly wide spectrum of wheat types (species and varieties) in a quest to create exceptional breads, almost regardless of the intrinsic functionality of the flour used. This trend is leading to a wonderful array of breads being produced by artisans worldwide who are exploring new horizons in flavor, aroma, and texture.

Acknowledgments

I thank Marie-Louise Risgaard, Mel Darbyshire, Jeff Yankellow, Martin Philip, and George DePasquale for enduring my questioning during their interviews. I also thank the USDA Western Wheat Quality Laboratory for the flour, dough, and bread data, and PT Pundi Kencana, in collaboration with U.S. Wheat Associates, for the extensograph and alveograph data. Thanks also to the following people for the instruction and discussions that have led me to my current understanding of artisan breads: Craig Ponsford, Richard Miscovich, Jeffery Hamelman, Jonathan Bethony, Michel Suas, Mac McConnell, Sam Fromartz, Dave Miller, Melina Kelson, Solveig Tofte, Josie Baker, and countless others, to whom I apologize for not naming. Thanks also to the Bread Bakers Guild of America, the Intergalactic Bakers Federation, and the San Francisco Baking Institute for instruction, inspiration, and information.

References References

- AACC International. Method 10-10.03, Optimized Straight-Dough Bread-Baking Method. Approved Methods of Analysis, 11th ed. Published online at http://methods.aaccnet.org. AACC International, St. Paul, MN.

- Arendt, E. K., Ryan, L. A., and Dal Bello, F. Impact of sourdough on the texture of bread. Food Microbiol. 24:165, 2007.

- Békés, F., Gianibelli, M. C., and Wrigley, C. W. The gluten proteins of the wheat grain in relation to flour quality. Page 375 in: The Encyclopedia of Food Grains, 2nd ed. Volume 3: Grain-Based Products and Their Processing. C. Wrigley, H. Corke, K. Seetharaman, and J. Faubion, eds. Academic Press, Oxford, 2016.

- Beranbaum, R. L. The Bread Bible. W. W. Norton & Company, New York, 2003.

- Borrelli, G. M., and Trono, D. Molecular approaches to genetically improve the accumulation of health-promoting secondary metabolites in staple crops—A case study: The Lipoxygenase-B1 genes and regulation of the carotenoid content in pasta products. Int. J. Mol. Sci. 17:1177, 2016.

- Calvel, R., Wirtz, R. L., and MacGuire, J. The Taste of Bread: A Translation of Le Goût du Pain, Comment le Préserver, Comment le Retrouver. Springer Science+Business Media LLC, New York, 2001.

- Cauvain, S. P., ed. Breadmaking: Improving Quality, 2nd ed. Woodhead Publishing, Cambridge, 2012.

- Dobraszczyk, B. Analysis of dough rheology in breadmaking. Page 343 in: The Encyclopedia of Food Grains, 2nd ed. Volume 3: Grain-Based Products and Their Processing. C. Wrigley, H. Corke, K. Seetharaman, and J. Faubion, eds. Academic Press, Oxford, 2016.

- Forestier, D. Technical baking: Wheat & flour classification. Bread Bakers Guild Am. Newsl. 1(5):6, 1993.

- Færgestad, E. M., Molteberg, E. L., and Magnus, E. M. Interrelationships of protein composition, protein level, baking process and the characteristics of hearth bread and pan bread. J. Cereal Sci. 31:309, 2000.

- Gobbetti, M., Rizzello, C. G., Di Cagno, R., and De Angelis, M. How the sourdough may affect the functional features of leavened baked goods. Food Microbiol. 37:30, 2014.

- Gänzle, M. G. Sourdough bread. Page 309 in: Encyclopedia of Food Microbiology, vol. 1, 2nd ed. C. A. Batt and M. L. Tortorello, eds. Elsevier Ltd., Amsterdam, 2014.

- Gänzle, M. G., Loponen, J., and Gobbetti, M. Proteolysis in sourdough fermentations: Mechanisms and potential for improved bread quality. Trends Food Sci. Technol. 19:513, 2008.

- Hamelman, J. Bread: A Baker’s Book of Techniques and Recipes, 2nd ed. John Wiley & Sons, Inc., Hoboken, NJ, 2013.

- Hammed, A. M., and Simsek, S. Hulled wheats: A review of nutritional properties and processing methods. Cereal Chem. 91:97, 2014.

- Harinder, K., and Bains, G. S. High a-amylase flours: Effect of pH, acid, and salt on the rheological properties of dough. Cereal Chem. 67:588, 1990.

- Hoseney, R. C., and Brown, R. A. Mixograph studies. V. Effect of pH. Cereal Chem. 60:124, 1983.

- Huff, T. Wheat flour: A technical perspective. Breadlines 14(3):10, 2006.

- Huys, G., Daniel, H. M., and De Vuyst, L. Taxonomy and biodiversity of sourdough yeasts and lactic acid bacteria. Page 105 in: Handbook on Sourdough Biotechnology. M. Gobbetti and M. Gänzle, eds. Springer Science+Business Media LLC, New York, 2013.

- Jayaram, V. B., Cuyvers, S., Lagrain, B., Verstrepen, K. J., Delcour, J. A., and Courtin, C. M. Mapping of Saccharomyces cerevisiae metabolites in fermenting wheat straight-dough reveals succinic acid as pH-determining factor. Food Chem. 136:301, 2013.

- Jayaram, V. B., Cuyvers, S., Verstrepen, K. J., Delcour, J. A., and Courtin, C. M. Succinic acid in levels produced by yeast (Saccharomyces cerevisiae) during fermentation strongly impacts wheat bread dough properties. Food Chem. 151:421, 2014.

- Kaplan, S. L. Good Bread Is Back: A Contemporary History of French Bread, the Way It Is Made, and the People Who Make It. Duke University Press, Durham, NC, 2006.

- Katina, K., Arendt, E., Liukkonen, K. H., Autio, K., Flander, L., and Poutanen, K. Potential of sourdough for healthier cereal products. Trends Food Sci. Technol. 16:104, 2005.

- Katina, K., Heiniö, R. L., Autio, K., and Poutanen, K. Optimization of sourdough process for improved sensory profile and texture of wheat bread. LWT Food Sci. Technol. 39:1189, 2006.

- Kim, Y., Huang, W., Zhu, H., and Rayas-Duarte, P. Spontaneous sourdough processing of Chinese Northern-style steamed breads and their volatile compounds. Food Chem. 114:685, 2009.

- Kucek, L. K., Dyck, E., Russell, J., Clark, L., Hamelman, J., et al. Evaluation of wheat and emmer varieties for artisanal baking, pasta making, and sensory quality. J. Cereal Sci. 74:19, 2017.

- Kweon, M., Slade, L., and Levine, H. Solvent retention capacity (SRC) testing of wheat flour: Principles and value in predicting flour functionality in different wheat-based food processes and in wheat breeding—A review. Cereal Chem. 88:537, 2011.

- Leonard, T. Technical baking. Bread Bakers Guild Am. Newsl. 2(3):6, 1994.

- Leonard T. A spectrum of flour: Extraction, ash, and type. A call {plea} for a uniform standard of nomenclature. Breadlines 22(4):34, 2014.

- Maher Galal, A., Varriano-Marston, E., and Johnson, J. A. Rheological dough properties as affected by organic acids and salt. Cereal Chem. 55:683, 1978.

- Mense, A. L., and Faubion, J. M. Effects of aging new crop wheat and flour on breadmaking quality and lipid composition. Cereal Foods World 62:4, 2017.

- Miscovich, R. From the Wood-Fired Oven: New and Traditional Techniques for Cooking and Baking with Fire. Chelsea Green Publishing, White River Junction, VT, 2013.

- Myhrvold, N., and Migoya, F. Modernist Bread. The Cooking Lab LLC, Bellevue, WA, 2017.

- Padulosi, S., Hammer, K., and Heller, J., eds. Hulled Wheats. Promoting the Conservation and Use of Underutilized and Neglected Crops. 4. Proceedings of the First International Workshop on Hulled Wheats, 21-22 July 1995, Castelvecchio Pascoli, Tuscany, Italy. Available online at www.bioversityinternational.org/uploads/tx_news/Hulled_wheat_54.pdf. International Plant Genetic Resources Institute, Rome, 1996.

- Paulley, G., Vázquez, D., Lysenko, E., and Preston, K. R. Development of a laboratory baking test for Uruguayan French style hearth bread using Canadian wheat flour. Can. J. Plant Sci. 84:949, 2004.

- Philip, M. Scoring and evaluation of artisan bread. Cereal Foods World 63:74, 2018.

- Poutanen, K., Flander, L., and Katina, K. Sourdough and cereal fermentation in a nutritional perspective. Food Microbiol. 26:693, 2009.

- Ross, A. S., and Kongraksawech, T. Characterizing whole-wheat flours produced using a commercial stone-mill, laboratory mills, and household single-stream flour mills. Cereal Chem. DOI: 10.1002/cche.10029. 2017.

- Salovaara, H., and Valjakka, T. The effect of fermentation temperature, flour type, and starter on the properties of sour wheat bread. Int. J. Food Sci. Technol. 22:591, 1987.

- Suas, M. Advanced Bread and Pastry: A Professional Approach. Delmar Cengage Learning, Clifton Park, NY, 2008.

- Tait, S. P. C., and Galliard, T. Oxidation of linoleic acid in doughs and aqueous suspensions of wholemeal flours: Effects of storage. J. Cereal Sci. 8:55, 1988.

- Tanaka, K., Furukawa, K., and Matsumoto, H. Effect of acid and salt on farinogram and extensigram of dough. Cereal Chem. 44:675, 1967.

- Tronsmo, K. M., Færgestad, E. M., Longva, Å., Schofield, J. D., and Magnus, E. M. A study of how size distribution of gluten proteins, surface properties of gluten and dough mixing properties relate to baking properties of wheat flours. J. Cereal Sci. 35:201, 2002.

- U.S. Wheat Associates. 2017 Crop quality report. Published online at www.uswheat.org/cropquality. USW, Arlington, VA, 2017.

- Wehrle, K., Grau, H., and Arendt, E. K. Effects of lactic acid, acetic acid, and table salt on fundamental rheological properties of wheat dough. Cereal Chem. 74:739, 1997.

- Wrigley, C., Asenstorfer, R., Batey, I., Cornish, G., Day, L., Mares, D., and Mrva, K. The biochemical and molecular basis of wheat quality. Page 495 in: Wheat: Science and Trade. B. F. Carver, ed. Wiley-Blackwell, Hoboken, NJ, 2009.

- Yankellow, J. Defining artisan: What it is and what it means. Cereal Foods World 63:52, 2018.

|